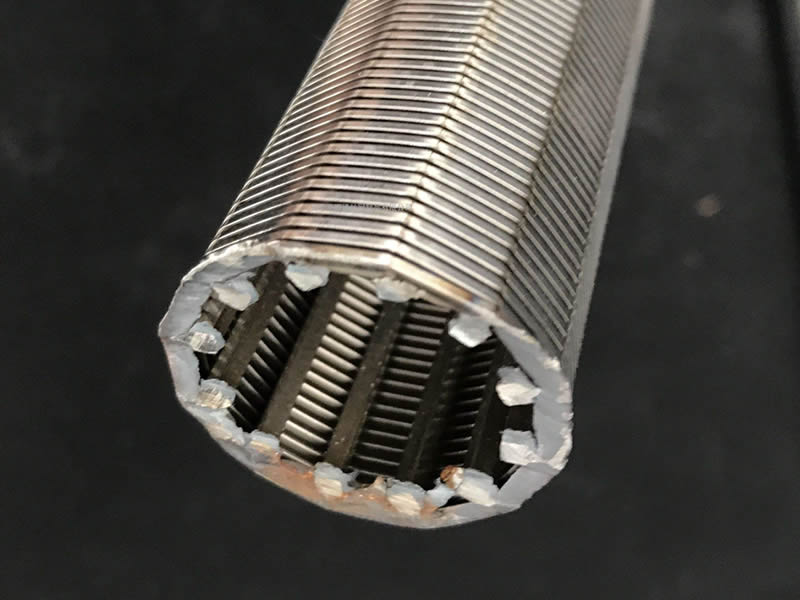

Wedge Filter Screen

Product Description

Wedge wire screen is widely used throughout the world for water, oil & gas wells, and is the dominant screen type used in the water well industry. The welded stainless steel wire wrap screen is made up of rods and profile wire. The rod can be round wire, triangular wire or trapezoid wire. The profile wire is triangular wire (V-shaped wire). This type of wire wrap screen has a structure and high open area, as well as accurate slot dimension. The wire is attached to the rods by welding, producing rigid one-piece units having high strength characteristics at minimum weights. Slot opening for screens are manufactured by spacing successive turns of the outer wire to produce the desired slot size. All slots should be clean and free of burrs and cuttings. Each slot opening between adjacent wires is V-shaped, from the special shape of wire used to form the screen surface. The V-shaped openings designed to be non-clogging, narrowest at the outer face and widen inwardly.

Wedge wire screen can be used in both Gravel Pack and Stand Alone Screen (direct retention) applications. Screens are available in a range of sizes and specifications, including outside diameter, material type, the geometry and dimension of the screen slots, and so on.

Features & Benefits

1. V-Shaped Slots — Openings shaped like a "v" that open toward the inside of the well tend to allow the particles that are just barely smaller than the width of the slot pass. In other shapes of openings, these particles would get caught in the screen and clog it.

2. Very Large Open Area — This design gives continuous slot and hence the open area for water to enter is more than 2 times that of conventional slotted pipes of any size and slot opening. This allows more water to enter at much lesser frictional head loss and the efficiency of tube well is improved appreciably.

3. Better Sand Filtration — Due to specialize manufacturing process, wide range of slot opening is available down to 0.15mm to allow proper slot selection depending upon the size of sand in particular area. This gives better sand control and reduced pump maintenance and longer tube well life.

4. Low maintenance costs — Separation at the screen surface which can easily cleaned by scraping or back washing.

5. Maximum process output — Precise and continuous slot openings resulting in accurate separation without loss off media.

6. Energy Saving — Due to reduce frictional head losses and increased discharge, the pump load reduces the power required to pump same quantity of water. Power saving of around 20-25% is observed.

7. Chemical and thermal resistant — A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures. Each slot opening between adjacent wires is V-shaped, resulting from the special shape of the wire used to form the screen surface. The V-shaped openings, designed to be non-clogging, are narrowest at the outer face and widen inwardly. Continuous-slot screens provide more intake area per unit area of screen surface than any other type. For any given slot size, this type of screen has maximum open area.